SmCo magnet

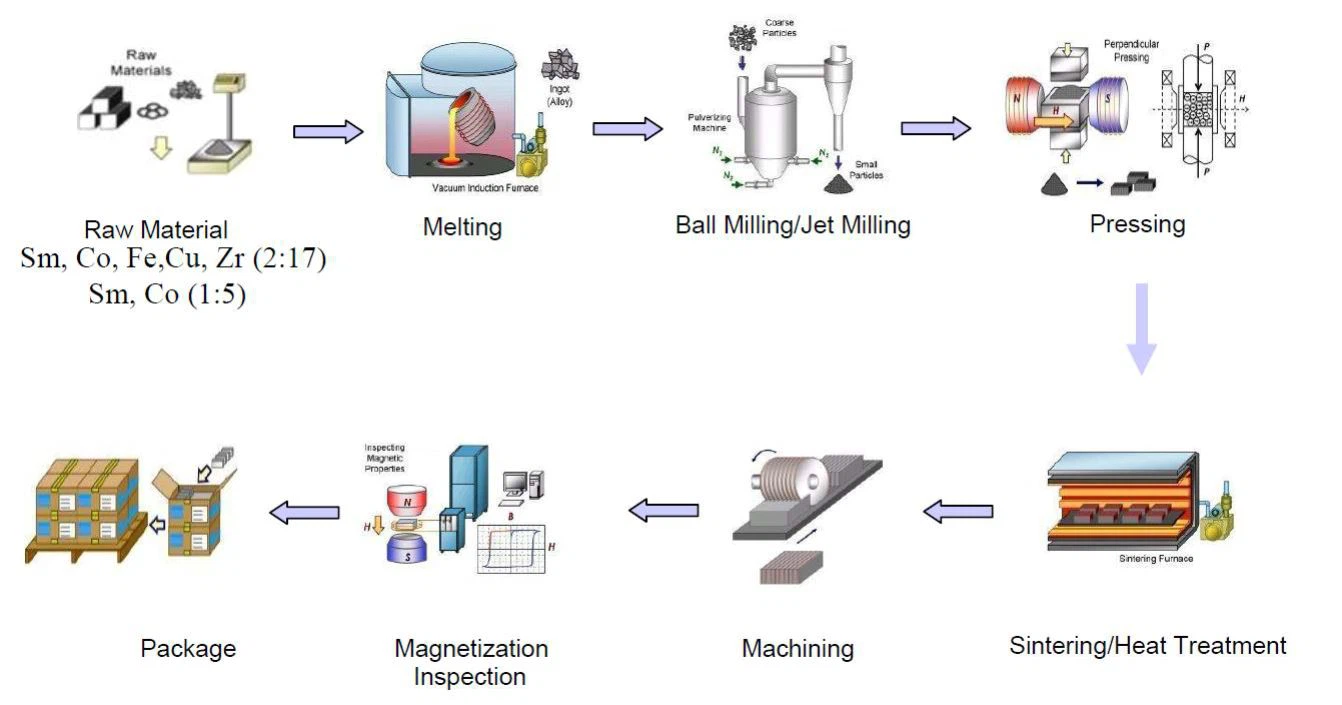

Samarium cobalt magnets are composed of samarium, cobalt and other rare earth materials by proportioning, and made by smelting, pressing and sintering, and which have high BH, corrosion resistance and oxidation resistance and extremely low reversible temperature coefficients. SmCo5 and Sm2Co17, (BH)max is in range of 16 to 32 MGOe. Maximum working temperature reaches 350°C. SmCo has an extreme low temperature coefficient and perfect corrosion resistance.

Compared with NdFeB magnets, SmCo magnets have stronger corrosion resistance, higher temperature stability and suitable for high temperature environments.

SmCo magnet are applied in Aerospace, National defense and Military industry, Microwave Devices, Communication Equipment, Medical Device, Instrument, Sensor, Motor, Magnetic cranes, etc.

Production flow diagram of SmCo magnet

Our SmCo magnets are all REACH and ROHS compliant and don’t contain any SVHC. It is produced according to ISO 9001 and ISO 14001 Quality Control Standards. PPAP, APQP, CPK/PPK, 8-D, CO, FTA are available. SmCo magnets can be made in blocks, discs, rings, arcs and many other shapes. If you require a bespoke SmCo magnets or magnetic assembly, Technical Support or our SmCo Magnet Technical Data Sheet, please contact us. If you need a quotation for an existing magnet shape or a bespoke shape, please contact us. We offer a highly competitive price for your reference.

Typical Magnetic Performance for SmCo magnet

Material | Grade | Remanence | Coercive Force | Intrinsic Coercive | Max Energy | Working Temp | ||||

Br | Hcb | Hcj | (BH)max | |||||||

T | KGs | KA/m | KOe | KA/m | KOe | KJ/m³ | MGOe | ℃ | ||

SmCo5 | XG18 | 0.85-0.90 | 8.5-9.0 | 650-700 | 8.3-8.8 | 1194-1830 | 15-23 | 127-143 | 16-18 | ≤250 |

SmCo5 | XG20 | 0.90-0.94 | 9.0-9.4 | 666-725 | 8.5-9.1 | 1194-1830 | 15-23 | 143-159 | 18-20 | ≤250 |

SmCo5 | XG22 | 0.94-0.97 | 9.4-9.7 | 700-748 | 8.9-9.4 | 1194-1830 | 15-23 | 159-175 | 20-22 | ≤250 |

SmCo5 | XG24 | 0.97-1.02 | 9.7-10.2 | 720-780 | 9.2-9.7 | 1194-1830 | 15-23 | 175-195 | 22-24 | ≤250 |

SmCo5 | XG18H | 0.85-0.90 | 8.5-9.0 | 650-700 | 8.3-8.8 | ≥1830 | ≥23 | 127-143 | 16-18 | ≤250 |

SmCo5 | XG20H | 0.90-0.94 | 9.0-9.4 | 666-725 | 8.5-9.1 | ≥1830 | ≥23 | 143-159 | 18-20 | ≤250 |

SmCo5 | XG22H | 0.94-0.97 | 9.4-9.7 | 710-748 | 8.9-9.4 | ≥1830 | ≥23 | 159-175 | 20-22 | ≤250 |

SmCo5 | XG24H | 0.97-1.02 | 9.7-10.2 | 730-780 | 9.2-9.8 | ≥1830 | ≥23 | 175-195 | 22-24 | ≤250 |

Sm2Co17 | XGS20L | 0.90-0.94 | 9.0-9.4 | 533-732 | 6.7-9.2 | 636-955 | 8-12 | 143-159 | 18-20 | ≤250 |

Sm2Co17 | XGS22L | 0.94-0.97 | 9.4-9.7 | 533-740 | 6.7-9.3 | 636-955 | 8-12 | 159-175 | 20-22 | ≤250 |

Sm2Co17 | XGS24L | 0.97-1.02 | 9.7-10.2 | 541-756 | 6.8-9.5 | 636-955 | 8-12 | 175-191 | 22-24 | ≤250 |

Sm2Co17 | XGS26L | 1.02-1.05 | 10.2-10.5 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 191-207 | 24-26 | ≤250 |

Sm2Co17 | XGS28L | 1.05-1.08 | 10.5-10.8 | 541-780 | 6.8-9.8 | 636-955 | 8-12 | 207-223 | 26-28 | ≤250 |

Sm2Co17 | XGS30L | 1.08-1.11 | 10.8-11.1 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 223-239 | 28-30 | ≤250 |

Sm2Co17 | XGS32L-A | 1.11-1.13 | 11.1-11.3 | 549-804 | 6.9-10.1 | 636-955 | 8-12 | 239-255 | 30-31 | ≤250 |

Sm2Co17 | XGS32L-B | 1.13-1.145 | 11.3-11.45 | 550-805 | 6.9-10.1 | 636-955 | 8-12 | 246-262 | 31-32 | ≤250 |

Sm2Co17 | XGS20M | 0.90-0.94 | 9.0-9.4 | 637-732 | 8.0-9.2 | 955-1433 | 12-18 | 143-159 | 18-20 | ≤300 |

Sm2Co17 | XGS22M | 0.94-0.97 | 9.4-9.7 | 645-740 | 8.1-9.3 | 955-1433 | 12-18 | 159-175 | 20-22 | ≤300 |

Sm2Co17 | XGS24M | 0.97-1.02 | 9.7-10.2 | 661-764 | 8.3-9.6 | 955-1433 | 12-18 | 175-191 | 22-24 | ≤300 |

Sm2Co17 | XGS26M | 1.02-1.05 | 10.2-10.5 | 685-788 | 8.6-9.9 | 955-1433 | 12-18 | 191-207 | 24-26 | ≤300 |

Sm2Co17 | XGS28M | 1.05-1.08 | 10.5-10.8 | 693-812 | 8.7-10.2 | 955-1433 | 12-18 | 207-223 | 26-28 | ≤300 |

Sm2Co17 | XGS30M | 1.08-1.11 | 10.8-11.1 | 700-828 | 8.8-10.4 | 955-1433 | 12-18 | 223-239 | 28-30 | ≤300 |

Sm2Co17 | XGS32L-A | 1.11-1.13 | 11.1-11.3 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 239-255 | 30-31 | ≤300 |

Sm2Co17 | XGS32L-B | 1.13-1.145 | 11.3-11.45 | 820-870 | 10.3-10.9 | ≥1433 | ≥18 | 239-255 | 31-32 | ≤300 |

Sm2Co17 | XGS20 | 0.90-0.94 | 9.0-9.4 | 653-732 | 8.2-9.2 | ≥1433 | ≥18 | 143-159 | 18-20 | ≤300 |

Sm2Co17 | XGS22 | 0.94-0.97 | 9.4-9.7 | 677-740 | 8.5-9.3 | ≥1433 | ≥18 | 159-175 | 20-22 | ≤300 |

Sm2Co17 | XGS24 | 0.97-1.02 | 9.7-10.2 | 693-772 | 8.7-9.7 | ≥1433 | ≥18 | 175-191 | 22-24 | ≤300 |

Sm2Co17 | XGS26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1433 | ≥18 | 191-207 | 24-26 | ≤300 |

Sm2Co17 | XGS28 | 1.05-1.08 | 10.5-10.8 | 756-820 | 9.5-10.3 | ≥1433 | ≥18 | 207-223 | 26-28 | ≤300 |

Sm2Co17 | XGS30 | 1.08-1.11 | 10.8-11.1 | 788-836 | 9.9-10.5 | ≥1433 | ≥18 | 223-239 | 28-30 | ≤300 |

Sm2Co17 | XGS32-A | 1.11-1.13 | 11.1-11.3 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 239-255 | 30-31 | ≤300 |

Sm2Co17 | XGS32-B | 1.13-1.145 | 11.3-11.45 | 820-870 | 10.3-10.9 | ≥1433 | ≥18 | 239-255 | 31-32 | ≤300 |

Sm2Co17 | XGS20H | 0.90-0.94 | 9.0-9.4 | 661-732 | 8.3-9.2 | ≥1990 | ≥25 | 143-159 | 18-20 | ≤350 |

Sm2Co17 | XGS22H | 0.94-0.97 | 9.4-9.7 | 685-740 | 8.6-9.3 | ≥1990 | ≥25 | 159-175 | 20-22 | ≤350 |

Sm2Co17 | XGS24H | 0.97-1.02 | 9.7-10.2 | 700-772 | 8.8-9.7 | ≥1990 | ≥25 | 175-191 | 22-24 | ≤350 |

Sm2Co17 | XGS26H | 1.02-1.05 | 10.2-10.5 | 756-796 | 9.5-10.0 | ≥1990 | ≥25 | 191-207 | 24-26 | ≤350 |

Sm2Co17 | XGS28H | 1.05-1.08 | 10.5-10.8 | 765-820 | 9.6-10.3 | ≥1990 | ≥25 | 207-223 | 26-28 | ≤350 |

Sm2Co17 | XGS30H | 1.08-1.11 | 10.8-11.1 | 796-836 | 10.0-10.5 | ≥1990 | ≥25 | 223-239 | 28-30 | ≤350 |

Sm2Co17 | XGS32-A | 1.11-1.13 | 11.1-11.3 | 820-860 | 10.3-10.8 | ≥1990 | ≥25 | 239-255 | 30-31 | ≤350 |

Sm2Co17 | XGS32-B | 1.13-1.15 | 11.3-11.5 | 830-880 | 10.4-11.0 | ≥1990 | ≥25 | 246-262 | 31-32 | ≤350 |

Sm2Co17 | XGS16LT | 0.81-0.85 | 8.1-8.5 | 605-669 | 7.6-8.4 | ≥1592 | ≥20 | 111-127 | 14-16 | ≤300 |

Sm2Co17 | XGS18LT | 0.85-0.90 | 8.5-9.0 | 629-708 | 7.9-8.9 | ≥1592 | ≥20 | 127-143 | 16-18 | ≤300 |

Sm2Co17 | XGS20LT | 0.90-0.94 | 9.0-9.4 | 661-732 | 8.3-9.2 | ≥1592 | ≥20 | 143-159 | 18-20 | ≤300 |

Sm2Co17 | XGS22LT | 0.94-0.97 | 9.4-9.7 | 685-740 | 8.6-9.3 | ≥1592 | ≥20 | 159-175 | 20-22 | ≤300 |

Physical properties of SmCo magnet

Material | Modulus of elasticity | Ultimate tensile strength | Density | Electrical Resistivity | Curie temperature | Recoil permeability | Temp. Coeff. of Br |

SmCo5 | 23 x 106 psi | 6 x 103 psi | 8.2 g/cm3 | 5 µ-ohm-cm/cm2 | 700-750 ℃ | 1.00-1.05 | -0.045% / ℃ |

Sm2Co17 | 17 x 106 psi | 5 x 103 psi | 8.4 g/cm3 | 86 µ-ohm-cm/cm2 | 800-850 ℃ | 1.00-1.10 | -0.03 % / ℃ |

Hot Tags: smco block magnet, China smco block magnet suppliers, manufacturers, SmCo Block Magnet, Permanent Alloy Magnets, Rubber Magnet, SmCo Disc Magnet, SmCo Arc Magnet, SmCo Ring Magnet